A Simple Solution To Plastic And Polymer Problems

December 27, 2021

If you’re having trouble with the Plastics and Resins error code on your computer, check out these troubleshooting tips.

Recommended: Fortect

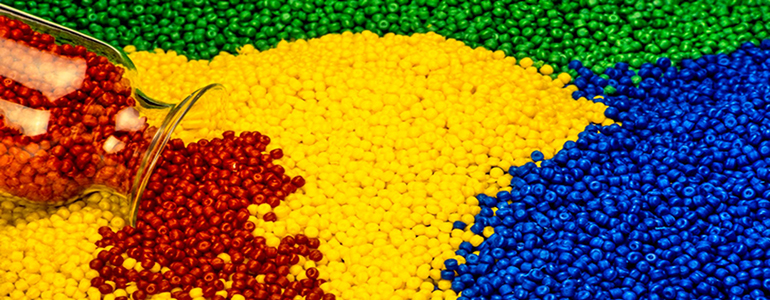

Most polymers, including poly (ethene) and additionally poly (propene), are not biodegradable. This means that microorganisms cannot destroy it, so they: If removed carelessly, cause filling problems. remain in landfills for many years.

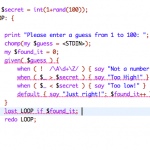

Top Ten Troubleshooting Tips for Technical and Commercial Polymer Casting.

Recommended: Fortect

Are you tired of your computer running slowly? Is it riddled with viruses and malware? Fear not, my friend, for Fortect is here to save the day! This powerful tool is designed to diagnose and repair all manner of Windows issues, while also boosting performance, optimizing memory, and keeping your PC running like new. So don't wait any longer - download Fortect today!

Many bags absorb the atmosphere with moisture; The absorption information depends on each resin type. Moisture in the granules, even if it is usually surface condensation, can cause problems caused by final molded parts made from engineering polymers. Many types of adverse effects can occur, including machining problems, poor surface finish of castings, or loss of mechanized properties. Read all about the moisture content of granules.

Currently, in the development of parts from ready-made polymers in solutions, information obtained using such complex methods as computer-aided design, finite element analysis and calculation of mold yield is used. Despite the fact that theyuseful, they sparkle, but sometimes do not sufficiently take into account the importance of a correct feeding schedule. This article considers the article as a basis for the correct design of delivery systems suitable for semi-crystalline polymers.

This can happen with all thermoplastics. As the demands on end products increase for this reason, the amount of additives and preservatives like modifiers, flame retardants, etc. Read the full article on mold.

Since part of the position of the gingerbread is dictated by designers and stucco plates, this article is written for people. However, injection molding technicians should also be present during the planning phase to assess problems. Read the full article on Posture Gate.

But the problem with plastic cards is that most of them are not biodegradable. It does not rot like documents or food, but it hangs easily in this area for hundreds of No. 800 million tons of plastic are grown every year, of which 40% is considered disposable – plastic that we only use as it was thrown into the bin.

In practice, many injection molders who do their job based on their experience with amorphous polymers often have shorter holding times and longer cooling times. Unfortunately, this approach also tends to be used for semi-crystalline polymers, whichs are available, for example, as POM (acetal), PA (nylon), PBT combined with PET (polyester). This article discusses some of the key points to help support managers choose the most appropriate time to print. Read the full article on setup times.

For household waste throughout the city, plastic bags have become an excellent element in the household waste system. This has resulted in many harmful effects on the environment, including strangulation of animals, pollution, clogging of canals, rivers and streams and further distortion of the landscape.

Choosing the right melting point is critical to the quality of the part when molding semi-crystalline engineering polymers. Typically, the tolerance limit is estimated to be lower than when processing amorphous resins. The groove in the machine frame influences the properties of this particular end product. In the fifth chapter of this ten-part series, authors typically address the melting points during the formation of POM (= acetal), PA (= nylon), PBT, and PET (polyester). Read the full article on fusion.

The most common problems or errors that commonly occur during plastic extrusion can be attributed to three main reasons: tool design, material selection, and processing.

When molding semi-crystalline plastics such as POM (acetal), (nylon), Pennsylvania PBT, and PET (polyester), it is important to ensure that the surface temperature of the accessories is generally correct. The main requirement for optimum is the refinement of the style and design of the instrument. Only if I say that consThe structure of the tool was correct, most of the founders would be able to produce high quality parts using temperature control. This requires close collaboration in the planning and development of tools to avoid subsequent occupational illnesses. Read the complete material on mold temperature.

Modern semi-crystalline thermoplastics such as POM (acetal), PA PBT (nylon) and PET (polyester) are preferred mainly for their superior automatic, thermal and electrical properties. Other advantages over amorphous materials are materials with better chemical resistance and a lower tendency to stress cracking. In many applications, a quality surface is an additional requirement. This story is intended to help eliminate possible surface imperfections. Read the full article Surface Finish.

In injection molding of partially architectural crystalline thermoplastics, the selection of the correct firing channel system determines the function of the tool and is molded My details. Here the temperature must be controlled much stricter than in the most important case with amorphous materials. The design and construction of the hot runner used, not to mention the installation, determines the properties of most precast concrete products. This article discusses the key points to consider when choosing the most suitable hot runner function for POM (acetal), PA (nylon), PBT, and PET (polyester). Read the Hot Runner article.

The most difficult problem in the design and manufacture of hard plastic parts is warpage.

Semi-crystalline materials such as POM (acetal), (nylon), poly-PBT, and PET (polyester) tend to deform more than amorphous ones. This point should be considered when designing molds and castings. If this did not happen, further complete improvement became almost impossible. This article discusses some of the causes of deformity and steps you can take to prevent and further reduce deformity. Read the full article on Warpage.

Problemen Oplossen In Kunststoffen En Polymeren

Rozwiazywanie Problemow W Tworzywach Sztucznych I Polimerach

Ustranenie Nepoladok V Plastikah I Polimerah

Depannage Des Problemes Dans Les Plastiques Et Les Polymeres

Resolucion De Problemas En Plasticos Y Polimeros

Risoluzione Dei Problemi In Materie Plastiche E Polimeri

Fehlerbehebung Bei Problemen In Kunststoffen Polymeren

플라스틱 및 폴리머의 문제 해결

Felsokning Av Problem I Plaster Och Polymerer

Solucao De Problemas Em Plasticos E Polimeros