The Best Way To Troubleshoot Typewriter Problems

September 4, 2021

Recommended: Fortect

It is worth reading these fixing recommendations if you get an error message on your computer regarding typewriter troubleshooting.

This page describes some of the common problems encountered by typewriters and users of the 1970s. Some problems can be fixed with simple knowledge and skills. minimum mechanical slope. Others require professional service.

The plate has slipped – detached directly from the inner core.

Solutions: Make sure paper sharing is not only enabled. The paper lock is an important lever (usually located at the end of the carriage) that relieves pressure from the transport wheels on the roller. In fact, you can straighten it before dipping it into the paper, as it will often be loaded with moderate curl. Size = “4”> Â flat

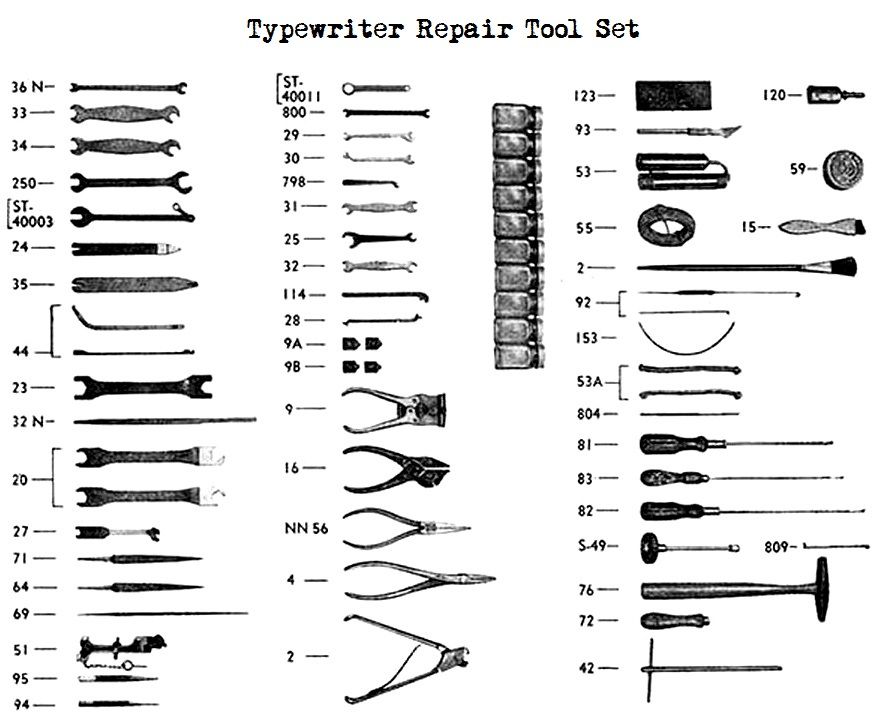

Solutions: A buggy lock can be difficult to find, or it can be designed to be nearly impossible to retrieve on your own. Make sure you have the manual, if you have one. Underwood notebooks have a clear latch on the left door on the right side of the bottom rail. Move any skids a few inches to the right to release them. Remington faces two portable systems. Early portalsOther devices required the shaft / handle to slide off the turntable at the right end of the rear carriage. The lock lever is located on the left side of all vehicles and is pressed against all release levers for the left sidecar. The new Remington (Model 5 / Streamliner / Deluxe) have a small knob on the left end of the main bogie that is the same color as previous models. The best lever usually has a small ball. Click on the lever that comes back to unlock the locking mechanism. I always mark the release handle with green tape before shipping. Always check your margin rates! This is another way to lock the sled for transportation. The price is shown at the top behind the machine. There are many different methods, but often the principle is the same. The earliest carry-over profit is set by pushing the margin limiter down somewhere and then moving it to the desired position. When they are in the center, move them towards the ends of the sled.  If the lace is torn, you can remove it yourself with about 60 woods Or separate laces and be patient. I like the line because IT won’t stretch (if you’re using heavier line) and won’t let oil through. To replace the customer’s lanyard, the shrunken lanyard must be removed (take notes / photos of how it should be attached to both the end of the cart and the pull-spring!) And even tie a new lanyard. Pull the drawbar drum by hand (surgical gloves are useful for gripping here) about 5 full turns or it cannot be rotated further. When customers are maximizing the mainspring, store it a full turn. If the drum slips out of your fingers, you probably got a slippery cut. You do this at your own peril and risk. Most stores – hundreds of them are still in operation – charge less than $ 40 for a one-time service. Repair / replacement of the mainspring is expensive and in most cases must be done by a specialist. Size = “4”> Solutions: If only a few keys are stuck, the method bars in Curved, curved. Slowly press the button and you will see the whole center as the scene at this guy’s local bar skyrockets. The forked chrome chunk that appears in the middle (right in front of the stripe) is a guide to font thickness. This helps to align the special type of strip in the last second before hitting. If a key is attached to it, it will most likely hit the rail on the shoulder. See which team it will fall into VERY, and gently press / fold the strip of font in the opposite direction. Typical rods bend easily and can break if too much pressure is applied. Once the box is in place, it will no longer stick. If typical tapes are stuck in different positions during the impact phase, the post (slot, piece of aluminum bent below the main impact point) is usually dirty. Many people say “just add a little oil,” but this is a misconception. The oil binds to a certain lubricant and typewriter, which degrades over time in a short period of time. BEFORE adding gasoline, try toremove as much dirt as possible. This can be done in most ways with a variety of elements; Q-tips, talent brushes, test tube brushes, etc. A small flashlight will also be constructive. After removing dirt, apply WD-40 or even machine oil liberally. Enter a complete line for each character to edit the important thing in the places of the segments. Even after the parts move smoothly, remove excess oil in the same way as dirt. It was not a complete refurbishment, it was simple cleaning / maintenance.  If more than one water point is blocked during printing, you are typing too quickly. You have when you need to let each type of panel almost return to its original position before families hit the next button. If you dial too fast, the stripes in the middle will collide and slide quickly. You can also see how characters point to each other without key presses (and ignore advances). You type so slowly that the handrails miss, but too fast for the buggy to move to the nextblowing storage location and locked until the next Natural hit. You usually hit the board as it moves. Hand typewriters also contain a precision instrument, although they are a work of art. There will most likely be a rhythm that needs to be used to type quickly and accurately. It takes practice, so don’t give it away!  If all of the generic tapes are stuck at the pressure point, that entry or rail segment is out of order, or the filament of the generic tape may rust. This adjustment / replacement must be performed by a professional mechanic. The cost can vary greatly from store to store. Thus, the prices are high, while the claimed $ 400 for this treatment. Run away from these places! Solutions: Replace the tape with a new one. Avoid big deals. Sometimes they sit on the shelves for years. Ko-Rec-Type branded tapes should also be avoided. They closed on December 8th and I bought all of their inventory. Anyone who sells co-rek today is selling very old products. The new tape is expected to cost no more than 9dollars per tape, including shipping to 48 US addresses. Many buyers charge between $ 12 and $ 17 a piece, not to mention tape shipping. They will also sell tapes for $ 2. But 99 charge $ 6 or $ 7 for shipping. I have 2 tapes for $ 18 or 95 tapes for $ 40.95. These prices are for USPS Free Priority Shipping to 48 US Lower Addresses.  The vibration of the tape is the part that moves up and down, not when pressed. There are usually three settings on a typewriter: Red – press down on the bottom half with tape if using only one black / red tape Are you tired of your computer running slowly? Is it riddled with viruses and malware? Fear not, my friend, for Fortect is here to save the day! This powerful tool is designed to diagnose and repair all manner of Windows issues, while also boosting performance, optimizing memory, and keeping your PC running like new. So don't wait any longer - download Fortect today! Black (blue dot) – as when entering text in the upper half for a group  White was used for the stencil. It is currently used to align the page after patching. These settings are changed at the time of delivery. Move the handle back “blue” to activate the vibrator. PS – There was no white tape 😉  The ribbon spool rotates with a gear. There may be several violations ( Strumento Per La Risoluzione Dei Problemi Della Macchina Da Scrivere

Recommended: Fortect

Fehlersuche Schreibmaschinen Tool

Probleemoplossing Schrijfmachine Tool

Outil De Depannage De Machine A Ecrire

문제 해결 타자기 도구

Ferramenta De Solucao De Problemas De Maquina De Escrever

Verktyg For Felsokning Av Skrivmaskiner

Instrument Dlya Ustraneniya Nepoladok Pishushej Mashinki

Rozwiazywanie Problemow Z Narzedziem Do Pisania

Solucion De Problemas De La Herramienta De Maquina De Escribir