How To Fix A Mistake In The Production Of Palm Kernel Oil

September 3, 2021

Recommended: Fortect

Sometimes, your computer may display an error code indicating palm kernel oil production. There can be several reasons for this problem. There are two kinds of natural oil that can be made; Crude palm oil is obtained by pressing the fleshy superfood and palm kernel oil, which can be obtained by crushing the kernel or main stone in the middle of each fruit. Today Indonesia and Malaysia account for over 85% of transnational supplies, but there are 42 countries that also produce oil.

5.1 MechanicalExtract

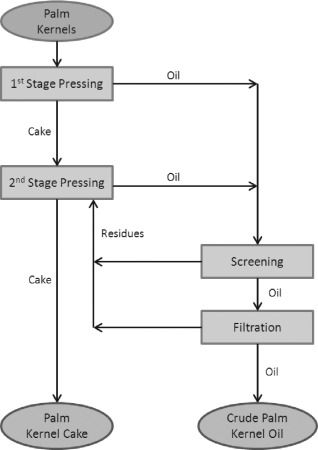

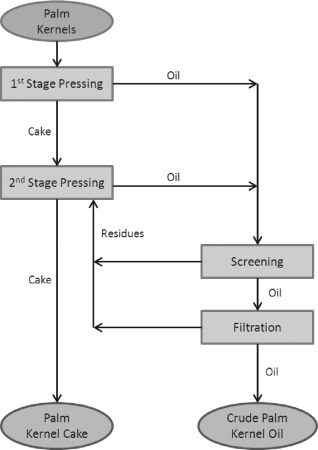

Mechanical removal is a procedure suitable for both smalland operations with great functionality. The three main stages of these processes are: (a)Core pretreatment, (b) screw pressing and (c) oil refining.

Line (A) is undoubtedly suitable for direct screw pressing for the extraction of carrots.Preliminary processing; Line (B) is for preprocessing the component’s kernel followed byscrew presses; and line C is followed by preprocessingScrew presses.

Good kernel preprocessing is the time it takes toextract the oil from the grains. First of all, you need to feed with grain constantly.externally cleaned materials that can lead to failure of the screw press increaseMaintenance costs, not to mention downtime and gift clogging. MagnetnySeparators are usually installed to remove scrap metal when it vibrates.Sieves are selected for filtering sand, stones or any other unwanted material.

Vibrating hammer mill, crusher or roller combinationboth break the grains into small particles. This process increasesSurface due to spikes, which leads to chipping. Core fragmentsthen cleaned in a roller mill. Large roller mill canconsist of five rollers stacked vertically on top of each otherSpin 200-300 rpm. The crust thickness decreases regularly.while he comes down from the big roll. This development of rupture rollersCell wall initiators. Flakes that make up the bottom pinch of a puppyThickness from 0.25 to 0.4 mm.

Then the kernel flakes are transported and the plateSteam conditioning with a specific purpose:

Adjust the water content of the food as best as possible based on the text. Level ;

Rupture of cell surfaces (initiated by lamination);

· Reduce the viscosity of the oil;

Coagulate what you need in food Separating this oil from proteinaceous materials.

Meat flows from top to bottom in the fifth compartment.Compartment within the group. A computer equipment shaker mixes food at every step.When heating steam trays, I would say pans, it can still be injected into any steam or steamCut off if necessary. Besides retention, temperature is an important variable.The moisture content of the weather. As a side dish, meals are usually grilled.humidity 3 portions 104-110 ° С up to.

Properly cooked food is finally fed to the auger press, whichusually consists of an intermittent spiral wire (worm) that also rotates ina fixed perforated cylinder called a cage or barrel. The submarine is forcedgoing through the action of spinning worms. Axial volumemoves by the auger, lowers from the end of the feed, so that it becomes the end of the discharge, i.e.Compression of flour as it passes through the barrel.

Oil drainage through the perforation connected to the liner.Kegs, although the fat-free pie is discharged through the ringOpening. To supportTemperature extremes that can damage the oil andQuality cake, worm shaft always with chilled circulating water, even ifThe keg is cooled from the outside with slightly cooled standard oil.

Thrown oil inevitably contains a certain amount”Penalties as well as legs” that should be missed. Oil from manufacturerspoured into the tank. It is either simply pumped into a decanter until it becomescoarse sieve to remove large amounts of solid impurities. Butter thenpump through a filter press to remove the remaining shades and in orderProduce clean oil before storage. Cupcakes coming out of the press come inthe shipment is transported for storage in bulk.

Indeed, as Figure 2 shows, circuit breakers never use the same thing.The process of mechanical extraction of vegetable oil. There are usually three options:direct screw pressing, partial and therefore complete pre-treatmentPreliminary processing. Mills

Recommended: Fortect

Are you tired of your computer running slowly? Is it riddled with viruses and malware? Fear not, my friend, for Fortect is here to save the day! This powerful tool is designed to diagnose and repair all manner of Windows issues, while also boosting performance, optimizing memory, and keeping your PC running like new. So don't wait any longer - download Fortect today!

Some people openly grind Balers withoutall preprocessing. Double presses are usually needed to test the effectiveness of the oil.Extraction. The actual screw presses used are less than 10 tons per unit each.Day.

Kernels first. broken into small fragmentsGrinding before screw pressing. Sometimes the prefix is also madeoff.

The preprocessing described earlier for the entire process is performed.in advance so that you can screw it on. Larger factories (50-500 tons perDay) select full pre-processing and even equipment that is usually found overseasEurope. FATECO and Faith Now Engineering form a complete line of small seriesOperator.

5.2 Extract

Solvent extraction events can be divided into three main phases.Unit operation: core preparation, oil recovery, additional treatment of the solvent frombutter and a bowl. For small businesses, enoughmention that the solution extraction process is an alternative to achieve high productivityMills. However, this process isCan be recommended for small businesses.

5.3 Traditional Rod With ClawsExtract

Extracting the kernel of a palm tree is a specialized process.completely different processors. They usually organize faster.as a group and not as scattered with palms as butter peels. BasicTransformers to be closed to palm oil refiners during the main season itself,When prices are at their lowest, buy dry nuts. Processing of nuts andOil production begins during the dry season, when all the pressure to win is overwhelming.Subsidized materials.

Thorough processing of palm oil begins with exfoliation.palm nut. The shelling should be carried out by breaking two stones.each nut and separates the core from the shell. This guideObsolete Nutcracker OperationStations.

Physical Nutcrackers are a mixture of corn kernels andShells to be separated. The kernel / shell splitting is usually donein the clay bath itself, which is a concentrated stickyI am a mixture of clay and water. vThe density of the clay bath is such that the shells sink, and the white grainsfloat on a piece of the mixture. Floating grains have been tasted in basketswashed in clean water and also dried. Sometimes the pods can have a core.the bath was thrown and.

A thorough oil extraction method involves cooking old palm kernels.in oil or simply heat dried nuts. Then the melted almonds are chopped orground in a motorized coffee grinder on the market. This dough is mixed with another smallThe amount of water heated and heated to release the palm kernel oil. Released oilregularly removed from the top.

Today, there are stations at the reception pointswell dried almonds for squeezing the base oil with a motorThe expeller is mechanized. (Fig. 20, 21)

Download this software and fix your PC in minutes.

The traditional method of making oil is to fry the kernels in old oil, or simply heat the corresponding dried nuts. The roasted grains can then be crushed or refined.grind into an absolute paste in a motorized coffee grinder. The paste is mixed with a small to medium amount of water and heated until the palm kernel oil is released.

Indonesia is generally the largest producer of palm oil, followed by Malaysia, with the two countries accounting for 84% of global palm production. Recently, an increase in the production of palm oil in the body has begun in South America through Colombia, Ecuador and Guatemala.

The palm kernel is the edible push of the oil palm fruit. The fruit contains two different oils: hand oil, which is extracted from the outside of the fruit, and company seed oil, which is extracted from the kernel.

Palmkernolproduktion

Produzione Di Olio Di Palmisti

Proizvodstvo Palmoyadrovogo Masla

Produccion De Aceite De Palmiste