Table of Contents

Toggle

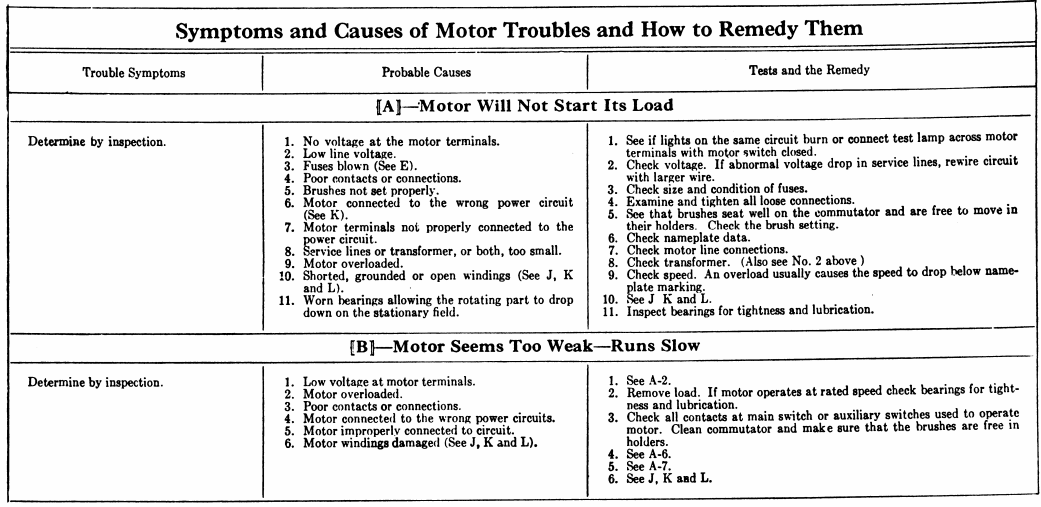

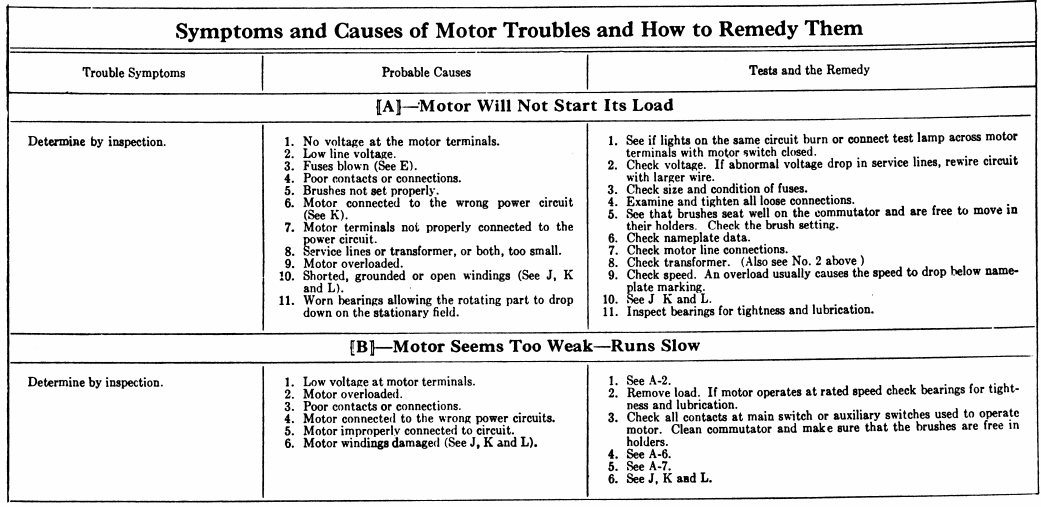

Here are some simple methods that can help you solve the problem described in the AC Motor Troubleshooting Guide.

Recommended: Fortect

Recommended: Fortect

Are you tired of your computer running slowly? Is it riddled with viruses and malware? Fear not, my friend, for Fortect is here to save the day! This powerful tool is designed to diagnose and repair all manner of Windows issues, while also boosting performance, optimizing memory, and keeping your PC running like new. So don't wait any longer - download Fortect today!

Use this resource to troubleshoot the best AC motor. If engine injuries are not possibleIf this list can be corrected, please contact your supplier.

Use this resource to troubleshoot the best AC motor. If engine injuries are not possibleIf this list can be corrected, please contact your supplier.

1st Engine Won’t Start On Initial Installation

- The motor is not connected correctly

- Check the diagram to make sure the kernel is wired correctly.

- A damaged motor and a windmill fall into the stator.

- To rub, turn the motor towards the shaft.

- Food, fix problems

- Check performance source, overload, fuses, controls, etc.

2. Engine Runs, Then Won’t Start

- A fuse or circuit breaker has blown.

- Replace fuse or reset circuit breaker.

- Stator permanently short-circuited or grounded (motor hums in addition to circuit breaker or fuse tripping)

- Check the rings for leaks. In the event of a leak, the motor must be replaced.

- The engine is overloaded or just blocked

- Make sure the cargo is freedressed. Compare the current consumption of the amplifier to the motor with the power rating indicated on the nameplate.

- Capacitor (with two-phase motors) may have start errors.

- Capacitor first. To test the capacitor, place an RX100 voltmeter on the scale and touch the capacitor terminals with a probe. If all capacitors are in good working order, the arrow can go to zero and tighten the resistance. Constant absolute resistance indicates a short circuit; a really high resistance indicates an open circuit.

3. Engine Runs But Dies

- voltage drop

- If the total voltage at the rated motor power is less than 90%, contact your company or make sure that any device other than the motor is not powered.

- Increased load

- Find out which experts say the load has not changed and the equipment is not tightened. If this is an application form, make sure that the gas flow has not changed.

4. Motor Condenses For Too Long.- Testing Acceleration

- monthly condenser failure according to preliminary instructions.

- Loud or rough bearings should be replaced by the motor supplier.

- Make sure the existing value is within 10% of the rated power indicated on the nameplate of the main motor. If not, call your power company or while other devices shut off the engine.

5. The System Is Working In The Wrong Direction

- Bad wiring

- Reconnect the motor part according to the wiring diagram supplied with the motor. Groschopp wiring plans can be found in the “wiring diagrams” of our resource component or on the individual motor pages.

6. Motor Overloaded / Thermal Protection Is Constantly Disabled

- Load too high

- Make sure the load is not overfilled. If a motor is an alternative to this, make sure the power rating is the same as the old motor I. If the corresponding previous engine was a special concept, the production engine may be prohibited from duplicating the output. Remove the load from the motor or check the current being drawn by the unloaded motor. If it is less than the full load indicated on the nameplate (applies to three-phase motors only).

- Ambient temperature too high

- Make sure the engine provides adequate air cooling. Most electric motors are designed to operate at a single ambient temperature of 40 ° C or below. (Note: A working machine may be hot.)

7. Engine Overheating

- Overload. Compare the nameplate of the actually installed (measured) amplifier with the dimensions

- Find and remove the real source of excessive friction in this engine or load. Reduce the load or replace the motor with at least a larger motor.

- Single-phase adjustment (three times in total)

- Check the current setting. Should beIt’s almost the same.

- Poor ventilation

- Check the external cooling fan to generally ensure that air is circulating properly in the cooling ducts. If excessive dirt has accumulated, clean the engine.

- Unbalanced (only three voltage phases)

- Check availability at all stages. It should always be about the same.

- Rotor in stator

- Tighten the through bolts.

- Overvoltage or undervoltage

- Check the input voltage on both phases of the common-mode motor to make sure the motor is running at the voltage indicated on the nameplate.

- Open rotating stator (three-phase only)

- Check the resistance of the main stator on three phases.

- Incorrect connections

- Inspect all electrical systems for proper terminations, clearances, mechanical, electrical and electrical integrity. See my theme outline.

8. Engine Vibrates

- The motor is not properly aligned with the load.

- Reinstallload.

- load in (direct balancing reader app)

- Remove the control unit from the load and check the permanent motor yourself. Make sure the generator shaft is not bent.

- Faulty drive bearings

- Test the engine yourself. If some bearings are defective, you will hear noises or feel unevenness.

- Load indicator on top (single phase only)

- Some vibrations from other light weights are standard. Consider upgrading to a smaller one due to engine vibration.

- Winding defective

- Check winding for short circuit or open circuit. Amplifiers that can be high too. If the repair winding is defective, the motor.

- High voltage

- Check someone else’s power supply to make sure the voltage is correct.

9. Bearing Failure

- The load on the motor may be too high or unbalanced.

- Check the load on the drive train and the tension of the drive train.belt to make sure it’s not too tight. An unbalanced load can also cause bearing failure.

- High background temperature.

- If the engine is used in a high temperature environment, a different type of sauce may be required for storage. You may need to contact the manufacturer.

- High engine temperature.

- Check and compare the actual motor you can load with the nominal motor power.

10. Capacitor Error

- Ambient temperature too high

- Make sure the ambient temperature does not exceed the permissible motor temperature (see above on the nameplate).

- Potential overvoltage on this motor (caused by lightning or other high transient voltage).

- If this is a common problem again, set an absolute overvoltage protection.

Download this software and fix your PC in minutes.

To test your system for a short to ground, you need to set a multimeter to a resistance and disconnect the motor from an appropriate power source. Then check each shift and look for endless readings. Alternatively, if you get an indicator connected to 0, there might be a problem with the power cord.

Stressful mechanical, topographic and electrical operating conditions can damage the motor. Electricity not working properly – these are winding faults caused by a good open contactor, poor connection, burnt connection, excessive heat, electrical overload, or ignoring power lines.

Guide De Depannage Du Moteur A Courant Alternatif

Guida Alla Risoluzione Dei Problemi Del Motore Ca

Ac Motor Probleemoplossing Gids

Ac 모터 문제 해결 가이드

Guia De Resolucion De Problemas Del Motor De Ca

Anleitung Zur Fehlersuche Bei Wechselstrommotoren

Przewodnik Rozwiazywania Problemow Z Silnikiem Pradu Przemiennego

Rukovodstvo Po Poisku I Ustraneniyu Neispravnostej Dvigatelya Peremennogo Toka

Guia De Solucao De Problemas De Motor Ac